|

|

The TPS or Throttle Position Sensor determines the angle of the Throttle Plate in the Throttle Body and depending on other info from the Map Sensor, Oxygen Sensor, and others, the ECU can better evaluate engine load and power needs.

To adjust it, locate the TPS on the Throttle Body. It is a black plastic sensor that is held in with what looks like 2 rivets. These rivets are in fact auto-torquing anti-tamper bolts that break off when the factory adjusts and tightens the TPS to the Throttle Body. Use a dremel to notch a little groove in the head of each rivet. Then take a flathead screwdriver and loosen them a little bit. If you don't have a dremel, you can try to use a pair of very small Vise Grip needle nose pliers but you risk fooking up your TPS.

Once loose, you can turn the TPS a little bit each way and this will change it's output voltage. The best way to adjust this is with one of the few Data Logging programs written by pgmfi forum members to set the measured TPS angle to close to 99%. To do this, get your datalogging working, then place the car in 5th gear at idle, then with your foot pressing hard on the brakes, let the clutch out in order to stall the engine. The ECU will continue to datalog. At this point, you want to adjust the sensor until it gives a full range of 0% at idle (exactly 0%, no higher) and close to 99% at full throttle. You may have to also adjust your throttle cable. If you were running around 90% with the throttle pedal to the floor, you'll notice a HUGE improvement in the off-idle transitions.

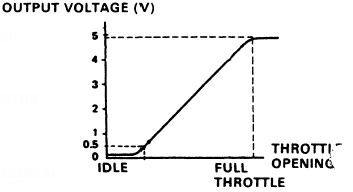

Now, if you don't have Data Logging working, well get to it punk ;) But in the meantime, you can use a use a Multi Meter with probes. Attach the the middle wire of the TPS and one of the outside ones, can't remember which one hehe. It should read 0.5v at "idle" and 4.5v at WOT. Once you position the sensor in the Throttle Body so it reads the correct voltages, just screw the rivets back in, or you can use new screws to replace them, something like an allenhead bolt is nice cause you don't need much room to use it back there ya know? Also, since the TPS doesn't require routine adjusting, you may want to put a tiny bit of Blue Loctite on it. Once it is tightened down, be sure to double check that the voltages are correct since the TPS can move from tightening the hold-down bolts.

Joseph Davis had this to say about TPS sensors: Reads .5 volts at idle, and 4.5 at WOT. Simple potentiometer. Everything inbetween falls where it may. Honda service literature claims anything over 4 volts TPS triggers open loop, but it seems to me that happens before that point."

To adjust it, locate the TPS on the Throttle Body. It is a black plastic sensor that is held in with what looks like 2 rivets. These rivets are in fact auto-torquing anti-tamper bolts that break off when the factory adjusts and tightens the TPS to the Throttle Body. Use a dremel to notch a little groove in the head of each rivet. Then take a flathead screwdriver and loosen them a little bit. If you don't have a dremel, you can try to use a pair of very small Vise Grip needle nose pliers but you risk fooking up your TPS.

Once loose, you can turn the TPS a little bit each way and this will change it's output voltage. The best way to adjust this is with one of the few Data Logging programs written by pgmfi forum members to set the measured TPS angle to close to 99%. To do this, get your datalogging working, then place the car in 5th gear at idle, then with your foot pressing hard on the brakes, let the clutch out in order to stall the engine. The ECU will continue to datalog. At this point, you want to adjust the sensor until it gives a full range of 0% at idle (exactly 0%, no higher) and close to 99% at full throttle. You may have to also adjust your throttle cable. If you were running around 90% with the throttle pedal to the floor, you'll notice a HUGE improvement in the off-idle transitions.

Now, if you don't have Data Logging working, well get to it punk ;) But in the meantime, you can use a use a Multi Meter with probes. Attach the the middle wire of the TPS and one of the outside ones, can't remember which one hehe. It should read 0.5v at "idle" and 4.5v at WOT. Once you position the sensor in the Throttle Body so it reads the correct voltages, just screw the rivets back in, or you can use new screws to replace them, something like an allenhead bolt is nice cause you don't need much room to use it back there ya know? Also, since the TPS doesn't require routine adjusting, you may want to put a tiny bit of Blue Loctite on it. Once it is tightened down, be sure to double check that the voltages are correct since the TPS can move from tightening the hold-down bolts.

Joseph Davis had this to say about TPS sensors: Reads .5 volts at idle, and 4.5 at WOT. Simple potentiometer. Everything inbetween falls where it may. Honda service literature claims anything over 4 volts TPS triggers open loop, but it seems to me that happens before that point."

| Library.TpsSensor moved from Library.TpSensor on 04 Mar 2004 - 00:43 by Home.blundar - put it back |

|

Copyright © 2002-present by the contributing authors. All material on this collaboration platform is the property of the

contributing authors, and is covered by the Non-Commercial Share-Alike License unless explicitly stated otherwise. |

|